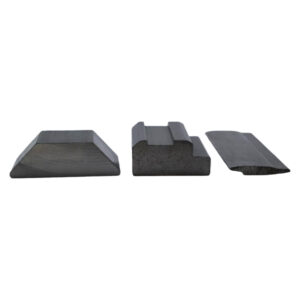

Custom Triangle Bar – Precision Engineered to Your Specifications

Product Overview

Our custom triangle steel bars represent the pinnacle of cold drawing technology, engineered to meet your most demanding and unique application requirements. We specialize in producing precision non-round profiles with complex geometries, delivering exceptional dimensional accuracy and superior mechanical properties for specialized industrial applications.

Key Advantages

• Complete Design Freedom: Create virtually any cross-sectional shape – beyond standard rounds, squares, and hexagons

• Precision Geometry Control: Maintain tight tolerances across complex profiles and subtle contours

• Material Versatility: Available in carbon steel, alloy steel, and stainless steel to match your performance needs

• Production Efficiency: Near-net-shape manufacturing reduces machining time and material waste

• Enhanced Properties: Cold working improves surface finish, strength, and dimensional stability

Technical Specifications

| Parameter | Capabilities |

|---|---|

| Material Grades | Carbon Steel (1018, 1045, C20, C45), Alloy Steel (4140), Stainless Steel (303, 304, 316) |

| Production Range | Minimum circumcircle diameter: 8mm, Maximum: 80mm |

| Profile Types | Irregular polygons, splined profiles, grooved sections, cam shapes, gear profiles, and fully custom designs |

| Tolerance Standards | Customized to application requirements, typically ±0.05mm to ±0.15mm |

| Surface Finish | Bright, ground, or as specified |

Common Applications

• Automotive Systems: Splined shafts, custom gear blanks, specialized guide rails

• Industrial Machinery: Custom tracks, guide rails, specialized conveyor components

• Electrical Engineering: Commutator segments, motor core components, special conductive parts

• Fastening Systems: Special security fasteners, anti-rotation components, custom locking parts

• Material Handling: Custom conveyor flights, guide rails, specialized tracking components

Customization Process

-

Design Consultation: Share your blueprint or application requirements

-

Technical Review: Our engineers assess manufacturability and optimize design

-

Tooling Development: Create custom dies and fixtures for your profile

-

Sample Production: Deliver prototypes for approval before full production

-

Quality Assurance: Implement strict dimensional and material verification

Quality Commitment

Every custom profile undergoes comprehensive inspection including:

-

3D coordinate measurement for complex geometries

-

Surface quality verification

-

Material certification and traceability

-

Mechanical property testing per application requirements

Why Choose Our Custom Solutions?

With specialized expertise in profile design and cold drawing technology, we transform your unique concepts into high-performance reality. Our engineering team works closely with you to optimize designs for manufacturability and cost-effectiveness while maintaining exacting quality standards.